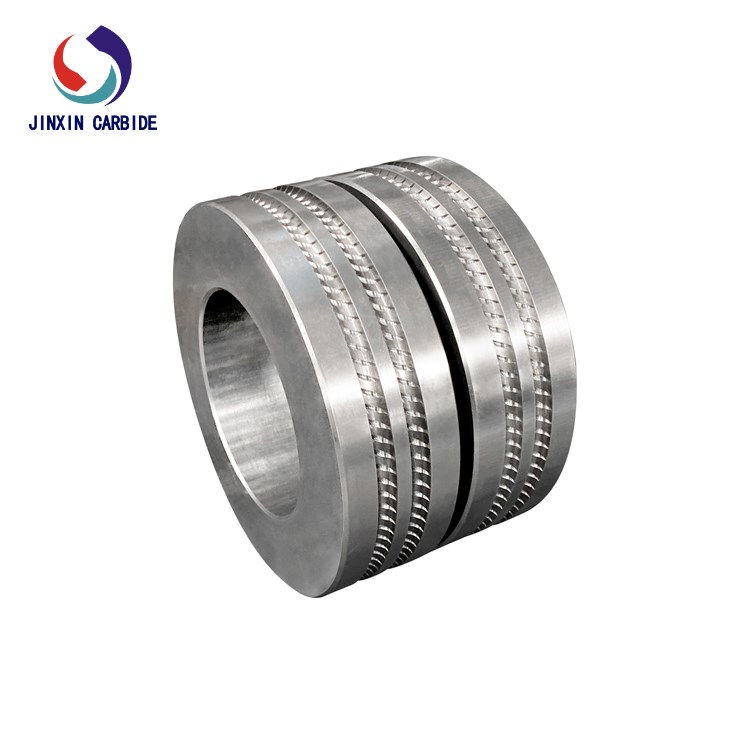

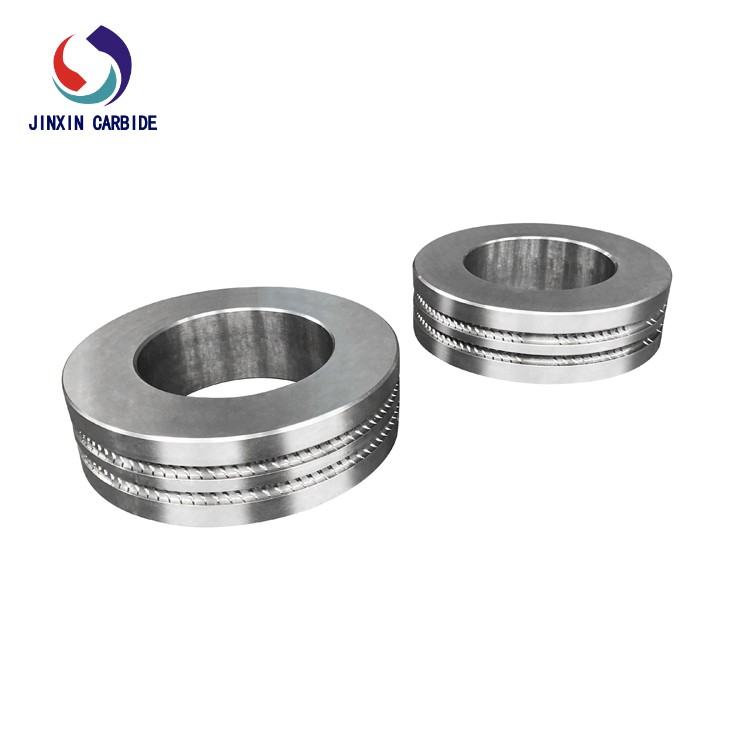

Warmgewalste wolfraamcarbide rolring

Merknaam : jinxin

Plaats van herkomst : China

MOQ: : 4 stuks

Details over de verpakking : Geval

Tijd om te bezorgen : 7-15 dagen

Capaciteit van de levering : 10 ton/maand

Materiaal : Wolfraamcarbide

Onze ringrollen van wolfraamcarbide zijn ideaal voor het snel walsen van staal, koper en aluminium. Met nauwkeurige afmetingen en een hoge thermische stabiliteit garandeert de warmgewalste ring van wolfraamcarbide consistente prestaties onder zware belasting. Jinxin hardmetalen rollen worden veel gebruikt in de metaalverwerkende industrie vanwege hun duurzaamheid en efficiëntie.

Beschrijving van de ringrol van wolfraamcarbide

Productnaam: Ringrol van wolfraamcarbide

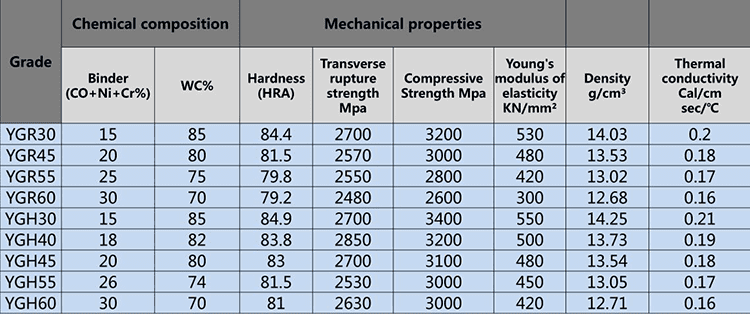

Gangbaar materiaal: YGR30, YGR45, YGR55, YGR60, YGH30, YGH40 etc.

Hieronder staan de bindmiddelgehaltes tussen 15% en 30% voor de aanbestedingsaanvragen:

YGR30: Goede taaiheid, slijtvastheid, corrosiebestendigheid en thermische scheurbestendigheid. Gebruikt in de meeste stellingen van de afwerkwalsen en in de achterste stellingen van gangbare walsen. YGR40: Goede taaiheid en thermische scheurbestendigheid, geschikt voor algemene doeleinden.

Toepassing van ringrollen van wolfraamcarbide

Wolfraamcarbiderollen worden veel gebruikt in de metaalbewerking, met name in de warmwalsindustrie, voornamelijk voor tussen- en eindbewerkingen om een superieure oppervlakteafwerking en maatvastheid van bewerkte metaalproducten te garanderen. Rollen worden ook vaak gebruikt voor het vlakmaken, ontkalken en richten van draad.

Wolfraamcarbide rollen kwaliteiten

YGR30: Goede taaiheid, slijtvastheid, corrosiebestendigheid en thermische scheurbestendigheid. Gebruikt in de meeste opstellingen van de afwerkwalsen en in de achterste opstellingen van gangbare walsen.

YGR40: Goede taaiheid en thermische scheurbestendigheid, geschikt voor algemene doeleinden. Gebruikt in de meeste opstellingen van de afwerkwalsen en in de achterste opstellingen van gangbare walsen.

YGR55: Goede slagvastheid. Wordt gebruikt in de voorbewerkingswalsen van warmgewalste wapeningsstaven en kan worden bewerkt met draaien en frezen.

YGR60: Goede slagvastheid. Wordt gebruikt voor het warmwalsen van wapeningsstaven en in de eerste en tweede fase van voorwalsmachines. Kan worden bewerkt met draaien en frezen.

Afmetingen van wolfraamcarbide rolringen:

Zie onderstaande informatie of volgens de vereisten van de klant.